Kastaş Sealing Technologies has recently introduced a new generation of guiding solution designed to meet the increasing performance demands in linear, oscillating, and slow-rotating motion systems.

Developed through extensive research and in-house engineering expertise, the KKB Guiding Tape provides a technically advanced and reliable alternative for guiding and supporting components in hydraulic systems.

Advanced Composite Structure

The KKB Guiding Tape is manufactured using a high-performance composite material, consisting of synthetic fibres and a specially formulated polyester resin. These components are optimally combined and cured under controlled process parameters. This construction enables superior dimensional stability, low wear rates, and enhanced mechanical strength – key attributes for guiding elements operating under dynamic loading and radial forces.

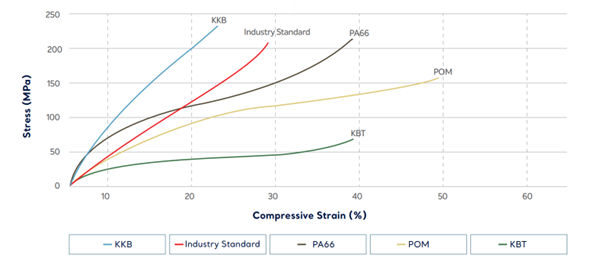

Compared to conventional guiding tape materials such as POM and PA66, the KKB composite provides:

- Up to 48% higher load-carrying capacity

- Up to 39% lower permanent deformation under identical conditions

- Excellent performance consistency at temperatures up to 80°C

These properties make it particularly well-suited to systems where tight tolerances, reduced maintenance, and an extended service life are priorities.

Low Friction & High Load Endurance

Thanks to its optimised fiber-resin matrix, KKB offers outstanding friction characteristics, reducing energy loss in hydraulic systems and minimising the risk of surface scoring or stick-slip effects. Its high compressive strength and low deformation under load allow for stable guiding of the piston or rod, ensuring consistent motion and reduced wear on mating components.

This makes KKB particularly well-suited for:

- Mobile hydraulic systems

- Construction and earth-moving equipment

- Agricultural machinery

- Press systems

- Crane and lifting applications

Precision Engineering & Flexible Integration

KKB is manufactured with tight dimensional tolerances to ensure a secure and precise fit within the groove. With its range of sizes and custom cut-to-length options, the KKB can easily be integrated into both standard and application-specific housing designs. Its consistent performance under load and temperature fluctuations enhances system reliability, making it a valuable component in performance-critical assemblies.

Developed by In-House Engineering Expertise

The development of KKB is the result of Kastaş’s continued investment in materials science, process engineering, and field application analysis. As part of its broader innovation strategy, Kastaş leverages its in-house R&D capabilities, including tribological testing, dynamic load simulation, and long-term durability analysis, to bring solutions like KKB to market that are rigorously validated against real-world application demands.

This approach ensures compliance with, and often exceeds, industry standards, delivering high-value solutions that support OEM-level engineering requirements.

Contribution to System Efficiency

The properties of the KKB contribute directly to energy efficiency, reduced heat generation, and extended system uptime. These advantages are in high demand across industries aiming to reduce the total cost of ownership and environmental impact without compromising operational reliability.

By minimising wear-related failures and optimising frictional behaviour, the KKB guiding tape plays a critical yet supporting role in overall system performance, particularly in high-load, long-cycle applications.

A Component of a Broader Sealing System Philosophy

KKB is designed to perform in conjunction with sealing elements complementing the sealing system as a whole by absorbing radial loads and preventing metal-to-metal contact. Integrating it into a sealing system supports longer seal life and reduces the risk of premature leakage, thereby contributing to higher system integrity.